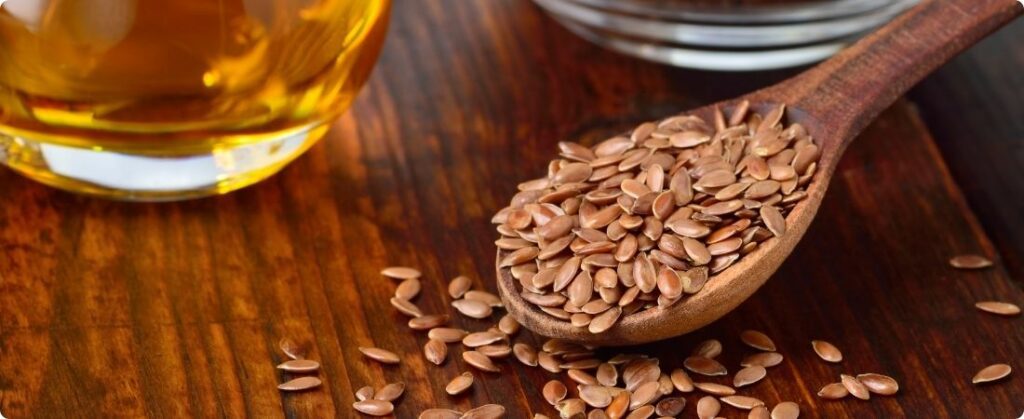

A plant-based alternative that combines tradition, innovation and environmental commitment

Faced with environmental emergencies and pressure for cleaner and more efficient solutions, the paint and varnish industry is looking for alternatives that combine technical performance and ecological responsibility. It is in this scenario that linseed oil, extracted from flax seeds, re-emerges as a protagonist — a natural, versatile and renewable input that can transform the way we cover the world.

Used for centuries in the formulation of paints and varnishes, linseed oil forms a solid, shiny and flexible film when exposed to oxygen. Ideal for surfaces such as wood and metal, it guarantees resistance, adhesion and a high-quality finish. In addition, it can be enriched with natural pigments and additives to enhance properties such as drying and waterproofing.

Environmental impact and sustainable advantages

The biggest difference, however, goes beyond aesthetics or durability: linseed oil represents a significant advance in reducing the industry's environmental footprint. By replacing petroleum-derived inputs — such as synthetic resins and solvents — it helps reduce emissions of volatile organic compounds (VOCs), which are associated with respiratory problems and air pollution. According to the EPA (US Environmental Protection Agency), this replacement can reduce VOC emissions by up to 80% during the application and curing of products.

Another important point is its sustainable life cycle. Flax, the raw material for oil, is a crop that requires little water. It is also resistant to pests. It is also ideal for regenerative agricultural practices, such as crop rotation. As a result, this model reduces the need for synthetic fertilizers and the environmental impact of cultivation, in line with the principles of sustainable agriculture.

At the end of their useful life, linseed oil-based coatings decompose naturally. This differentiates them from petrochemical materials, which do not degrade easily and remain in the environment for decades. Finally, this biodegradability reinforces their role in the circular economy, reducing waste and strengthening more responsible production chains.

Competitiveness, technology and future of the sector

Although the initial cost of linseed oil formulations may be higher, the long-term benefits — such as access to tax incentives, greater commercial competitiveness, environmental certifications and a positive brand image — make the investment highly advantageous. Companies such as AURO and LIVOS have already achieved seals such as European Ecolabel for adopting this input in their ecological paints, opening doors to new markets and conscious consumers.

With advances in research, challenges such as drying time are being overcome. New technologies are being developed with catalysts and nanomaterials that accelerate oxidation and increase the resistance of products, making linseed oil even more competitive compared to conventional solutions.

The adoption of sustainable raw materials, such as linseed oil, is not just a trend. It is a strategic choice. It is also a concrete response to the demands of the present. And, above all, it is a preparation for the challenges of the future. Companies that opt for this alternative position themselves as leaders in green innovation, prepared to serve increasingly demanding, conscious and regulated markets.

One step forward

The time to invest in sustainable solutions is now. And linseed oil could be the next step towards a cleaner, more efficient and competitive future.

By Diogo Carvalho

Review by Vanessa Ferreira